Title: A Comprehensive Guide to Capacitive Touch Components: Choosing the Right Class for Your Application

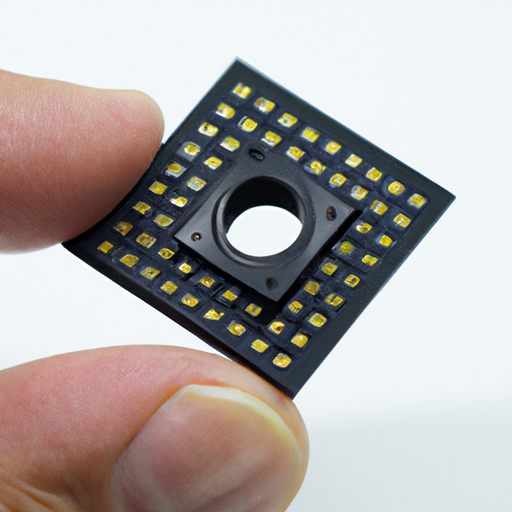

1. Understanding Capacitive Touch Technology: Before diving into the various component classes, it is essential to understand the basics of capacitive touch technology. Unlike resistive touchscreens that rely on pressure, capacitive touchscreens detect changes in electrical charge when a conductive object, such as a finger, comes into contact with the screen. This technology offers several advantages, including multi-touch support, enhanced durability, and improved optical clarity.

2. Capacitive Touch Component Classes: There are typically three main classes of capacitive touch components available in the market, each with its unique features and applications. Let's explore them in detail:

a. Surface Capacitive Touch: Surface capacitive touch is the most common class of capacitive touch technology. It consists of a transparent conductive layer applied to the surface of the display. This class offers excellent durability, high clarity, and resistance to scratches and chemicals. Surface capacitive touchscreens are widely used in consumer electronics, such as smartphones and tablets, due to their cost-effectiveness and reliability.

b. Projected Capacitive Touch (PCT): Projected capacitive touch, also known as PCT or PCAP, is a more advanced class of capacitive touch technology. It involves a grid of micro-fine wires embedded in the display's glass substrate, creating a matrix of touch-sensitive points. PCT offers superior touch accuracy, multi-touch support, and excellent optical clarity. It is commonly found in high-end smartphones, tablets, and industrial applications where precise touch input is crucial.

c. Mutual Capacitive Touch: Mutual capacitive touch is a specialized class of capacitive touch technology that enables multi-touch functionality. It utilizes a grid of electrodes on both the X and Y axes, allowing for simultaneous tracking of multiple touch points. Mutual capacitive touchscreens are commonly used in large-format displays, interactive kiosks, and automotive infotainment systems. They offer exceptional touch accuracy, responsiveness, and support for complex gestures.

3. Factors to Consider When Choosing a Capacitive Touch Component: Selecting the right capacitive touch component class for your application requires careful consideration of several factors. Here are some key aspects to keep in mind:

a. Application Requirements: Evaluate your application's specific requirements, such as touch accuracy, multi-touch support, durability, and environmental conditions. This will help determine which class of capacitive touch component is best suited for your needs.

b. Cost Considerations: Different classes of capacitive touch components vary in terms of cost. Surface capacitive touchscreens are generally more cost-effective, while PCT and mutual capacitive touchscreens tend to be more expensive due to their advanced features. Consider your budget constraints when making a decision.

c. Integration and Customization: Consider the ease of integration and customization options offered by the capacitive touch component. Some manufacturers provide ready-to-use touch modules, while others offer customizable solutions to meet specific design requirements.

d. Supplier Reputation and Support: Choose a reputable supplier with a track record of delivering high-quality capacitive touch components. Look for suppliers that offer technical support, documentation, and long-term availability of the chosen component.

4. Conclusion: Capacitive touch technology has become an integral part of our daily lives, enabling intuitive and seamless interactions with electronic devices. By understanding the different classes of capacitive touch components and considering the specific requirements of your application, you can make an informed decision when selecting the right component. Whether it's surface capacitive touch, projected capacitive touch, or mutual capacitive touch, each class offers unique features and benefits that can enhance the user experience in various applications.

Title: A Comprehensive Guide to Capacitive Touch Components: Choosing the Right Class for Your Application

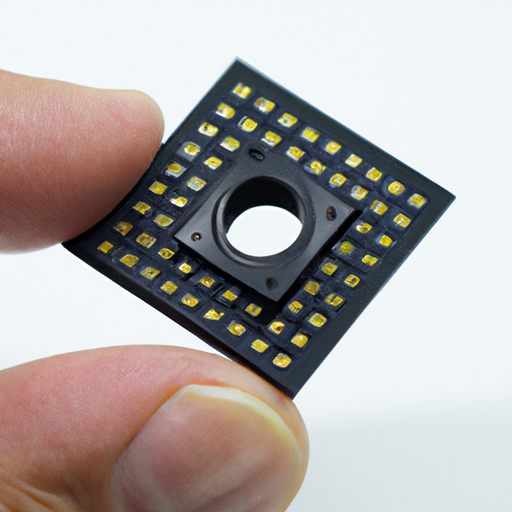

1. Understanding Capacitive Touch Technology: Before diving into the various component classes, it is essential to understand the basics of capacitive touch technology. Unlike resistive touchscreens that rely on pressure, capacitive touchscreens detect changes in electrical charge when a conductive object, such as a finger, comes into contact with the screen. This technology offers several advantages, including multi-touch support, enhanced durability, and improved optical clarity.

2. Capacitive Touch Component Classes: There are typically three main classes of capacitive touch components available in the market, each with its unique features and applications. Let's explore them in detail:

a. Surface Capacitive Touch: Surface capacitive touch is the most common class of capacitive touch technology. It consists of a transparent conductive layer applied to the surface of the display. This class offers excellent durability, high clarity, and resistance to scratches and chemicals. Surface capacitive touchscreens are widely used in consumer electronics, such as smartphones and tablets, due to their cost-effectiveness and reliability.

b. Projected Capacitive Touch (PCT): Projected capacitive touch, also known as PCT or PCAP, is a more advanced class of capacitive touch technology. It involves a grid of micro-fine wires embedded in the display's glass substrate, creating a matrix of touch-sensitive points. PCT offers superior touch accuracy, multi-touch support, and excellent optical clarity. It is commonly found in high-end smartphones, tablets, and industrial applications where precise touch input is crucial.

c. Mutual Capacitive Touch: Mutual capacitive touch is a specialized class of capacitive touch technology that enables multi-touch functionality. It utilizes a grid of electrodes on both the X and Y axes, allowing for simultaneous tracking of multiple touch points. Mutual capacitive touchscreens are commonly used in large-format displays, interactive kiosks, and automotive infotainment systems. They offer exceptional touch accuracy, responsiveness, and support for complex gestures.

3. Factors to Consider When Choosing a Capacitive Touch Component: Selecting the right capacitive touch component class for your application requires careful consideration of several factors. Here are some key aspects to keep in mind:

a. Application Requirements: Evaluate your application's specific requirements, such as touch accuracy, multi-touch support, durability, and environmental conditions. This will help determine which class of capacitive touch component is best suited for your needs.

b. Cost Considerations: Different classes of capacitive touch components vary in terms of cost. Surface capacitive touchscreens are generally more cost-effective, while PCT and mutual capacitive touchscreens tend to be more expensive due to their advanced features. Consider your budget constraints when making a decision.

c. Integration and Customization: Consider the ease of integration and customization options offered by the capacitive touch component. Some manufacturers provide ready-to-use touch modules, while others offer customizable solutions to meet specific design requirements.

d. Supplier Reputation and Support: Choose a reputable supplier with a track record of delivering high-quality capacitive touch components. Look for suppliers that offer technical support, documentation, and long-term availability of the chosen component.

4. Conclusion: Capacitive touch technology has become an integral part of our daily lives, enabling intuitive and seamless interactions with electronic devices. By understanding the different classes of capacitive touch components and considering the specific requirements of your application, you can make an informed decision when selecting the right component. Whether it's surface capacitive touch, projected capacitive touch, or mutual capacitive touch, each class offers unique features and benefits that can enhance the user experience in various applications.